At Technocrats India, we specialize in Zinc and Zinc alloy electroplating, providing reliable corrosion resistance and longevity for a range of components.

Incorporated in 2013, Technocrats India has been a reliable Tier-2 supplier to the automotive industry across Europe and the USA. As the industry evolves—driven by the rise of Electric Vehicles (EVs) and growing environmental awareness—we are proactively adapting to meet these changing demands. Our focus is on delivering sustainable, eco-friendly surface protection processes for both Internal Combustion Engine (ICE) and Electric Vehicle (EV) manufacturers, supporting their transition to a greener future.

To become a one-stop solution provider for quality services in all specialized metal finishing requirements.

To build long-term relationships with clients by providing exceptional customer service and pursuing business growth through innovation and advanced technology.

We believe in treating our customers with respect and faith. We grow through creativity, invention, and innovation. We integrate honesty, integrity, and business ethics into all aspects of our business functioning.

Regional expansion in the field of metal finishing and development of a strong base of key customers. Increase company assets and investments to support the development of services. Build a strong reputation in engineering processes and become a key industry player.

To diversify into critical and specialized product requirements based on sound technological foundations and market needs.

The company aims to achieve desired profitability every year and does not foresee major cash flow challenges. However, we currently maintain a borrowing relationship with Canara Bank, which we are committed to repaying as planned.

Technocrats India has specialized in Zinc and Zinc Alloy (Nickel, Tin, Cobalt, Iron) electroplating, consistently achieving up to 920 hours of red rust resistance in Neutral Salt Spray Testing (NSST).

Our plated components meet stringent OEM requirements even after heat ageing and physical stress such as crimping. We also have extensive experience in plating metals prone to hydrogen embrittlement, ensuring structural integrity and performance.

Technocrats India has successfully plated Zinc and Zinc alloys on pressure die-cast components, achieving the required white rust resistance.

With over 8 years of expertise in Tin plating, we are highly skilled in applying this coating across various substrates to meet diverse industrial needs.

Providing advanced alkaline zinc plating solutions for superior corrosion protection and durability.

Delivering premium corrosion resistance with Zinc-Nickel alloy plating, ideal for automotive and industrial applications.

Expert plating solutions for die-cast parts, ensuring maximum strength and corrosion protection.

Specialized plating techniques to prevent hydrogen embrittlement and ensure long-lasting mechanical integrity of your parts.

Providing superior electrical conductivity and corrosion resistance with our expert tin plating services on various substrates.

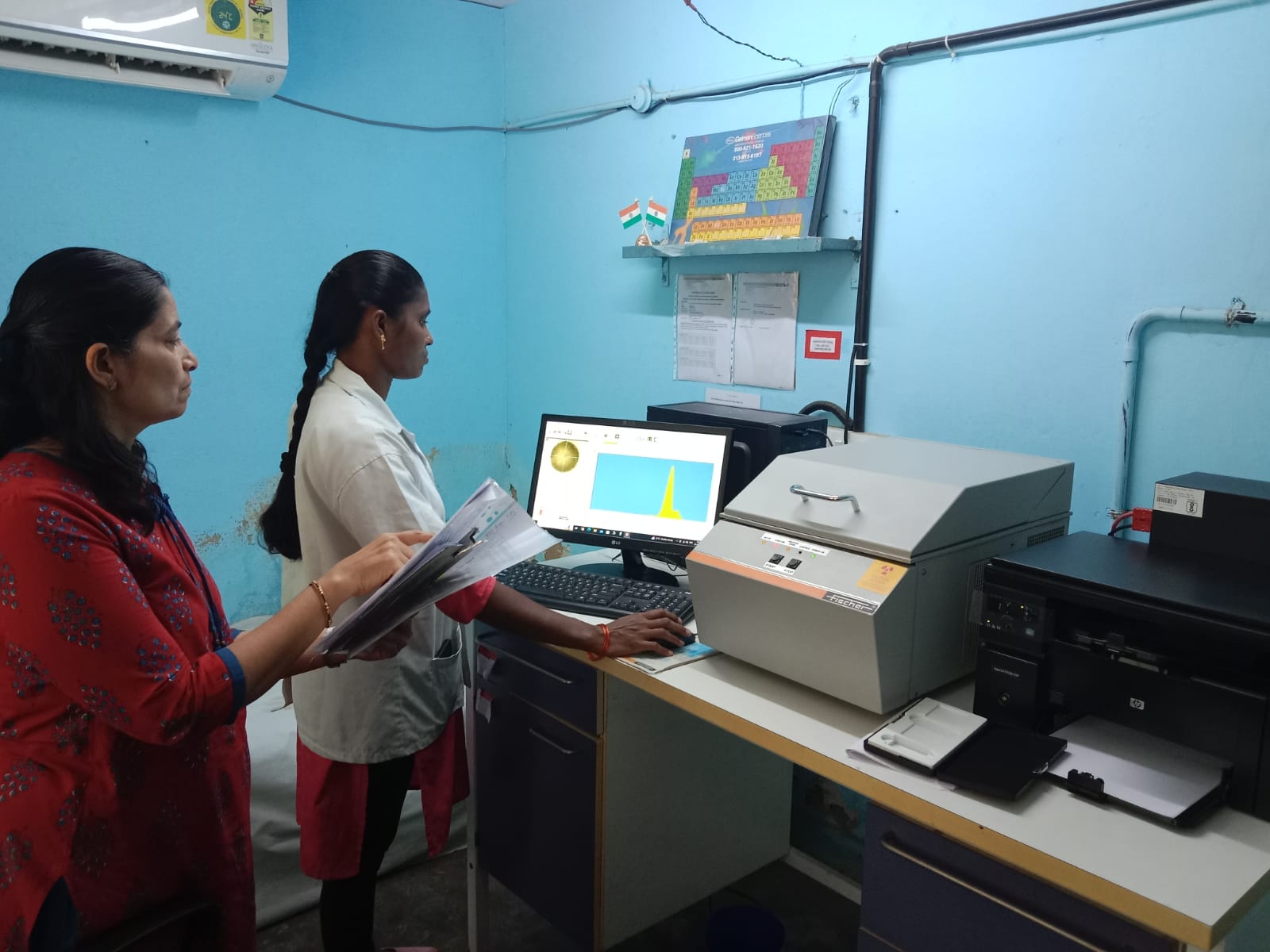

Accurate and non-destructive XRF measurements for precise coating thickness analysis across various materials and processes.

Hard-earned experience serving industries where requirements evolve rapidly. We consistently deliver quantifiable, high-quality results tailored to your specific needs.

Rigorous quality control processes ensure every component meets the highest standards. Our plating solutions consistently achieve 920+ hours of red rust resistance in NSST.

Quality and ethics are the cornerstone of all our business practices — today, tomorrow, and forever. We build relationships on trust and transparency.

State-of-the-art plating technology with precise XRF thickness measurement capabilities.

Proven expertise in automotive plating for both ICE and EV applications.

Reliable on-time delivery backed by efficient production planning.

Eco-friendly processes that meet evolving environmental regulations.

We ensure rigid control over the consumption of raw materials using technical data sheet-based calculations, minimizing wastage and rejections to maintain a competitive edge over others.

TCI aims to achieve the highest level of customer satisfaction and surpass it through Stringent Quality checks & timely delivery of components to its existing and new customers by Continually improving the systems by using global standards (ISO 9001:2015)

We pledge on-time delivery of quality components, ensuring customer satisfaction and trust.

Our centralized closed-loop business model follows the Plan, Do, Check, Act (PDCA) concept, ensuring continuous improvement and operational efficiency.